A CIO’s responsibilities include managing the synergy among people, process, and technology and ensuring that the organization’s IT supports its broader goals. However, IT is just one slice of the larger organization. Who uses the tech, how they use it, and even the choices behind which tech to use are all part of a larger value stream that gets delivered to the end customer.

CIOs thus have an integral, but not sole, role to play in the process of value stream mapping. It’s therefore important to understand how to build a VSM, how it benefits production processes, and a couple of considerations before getting started.

What is value stream mapping?

Value stream mapping (VSM) is a process of visualizing the people, processes, sites, and equipment involved in the stages of a production process. The concept of VSM derives from the lean manufacturing methodology. Lean principles aim to maximize value for the customer and reduce, if not eliminate, inefficiencies in the production process. In spite of its roots in the manufacturing context, value stream mapping has found broad application in a number of environments:

- DevOps

- Healthcare

- Project management

- Logistics

- Supply chain

Value stream mapping provides an overview of the entire production process from start to finish, whether it’s for a physical product or software. With this high-level visibility of the production process, VSM thus helps identify and remediate waste at its source. Waste in the CI/CD process, for example, isn’t so much related to materials as it is to time and information flows, such as idle or no-coding time.

Products or services rendered need to create as much value as possible for the customer. However, as a product or service expands or changes, the challenge is to add more value to the end user without sacrificing efficiency to the production process. VSM is therefore a means to process analysis and improvement.

VSM examples

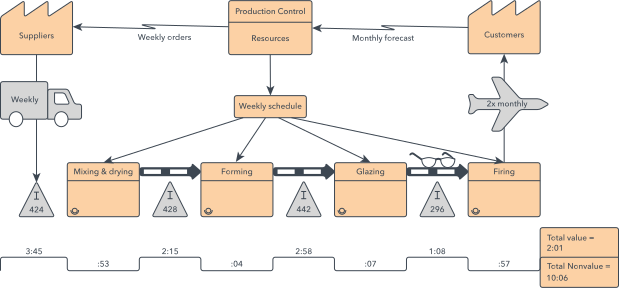

Developing a value stream map takes time. Since no production process occurs in a vacuum, a value stream map usually includes multiple layers to account for various stakeholders in production, including but not limited to:

- Suppliers

- Partners

- Facility locations

- Cross-functional teams

- Equipment

- Customers

Gaining an overview of how all parts and people work together, VSM surfaces opportunities to optimize the production process by visualizing bottlenecks, duplication, pain points, and other causes for inefficiency.

Value stream mapping can be done in low-tech ways, such as on a whiteboard or piece of paper. While those are good starting points, you’ll eventually want to graduate to a software tool. Given the complexity of creating a value stream map, there are luckily templates and software tools to assist, such as Lucidchart or Edraw.

Software solutions contain the common framework of symbols used in value stream mapping. Symbols are grouped into different categories to denote:

- General symbols, such as orders, warehouse, and transportation

- Inventories

- Processes

- Information flow

- Material flow

Symbols are often connected via lines or arrows to show the flow direction(s).

How to create a value stream map

To help CIOs, DevOps, or operations leadership successfully develop a value stream map, we’ve compiled a list of steps to take.

- Identify the problem. Which product or service needs improvement? Perhaps a particular product has garnered frequent customer complaints or higher-than-average returns or cancellations. That’s a good product or service to start with.

- Get buy-in at the top. To get leadership’s attention and win their approval for a VSM project, draw attention to an emerging problem, quantify its effects, and propose a plan to solve it.

- Prime the people involved. Hire a value stream manager or train at least the c-suite in value stream mapping.

- Walk in the customer’s shoes. Work backwards starting with the product or service from the customer’s viewpoint. This reveals opportunities for improvement but requires data from customer service (for complaints), logistics (for returns), and sales (for order or subscription cancellations).

- Start drawing. Still working backwards, map out the processes and flows of information involved in delivering the product or service. Information flows for a software company, for instance, would depict when and how code for a software update gets developed, committed, tested, and deployed. Mapping should be based on documentation and other forms of evidence rather than interviews or anecdotal evidence. Repeat this step several times, as you’ll gather more information each time you pass the chain of activities.

- Find value creators vs. value suckers. Evaluate each step of the process according to whether it’s adding or subtracting value for the customer in the end. Like step 4, this part of the process also requires data regarding output, time, and other metrics.

- Ideate a better way. The last step requires creativity, imagination, and most of all, a problem-solving mindset to draft a future state value stream map. The future state value stream map is essentially a roadmap of goals to achieve a more efficient production process based on findings in steps 5 and 6.

Benefits of value stream mapping

The benefits of value stream mapping outweigh the drawbacks. Among many advantages, VSM:

- Reduces or eliminates waste, boosting productivity and profit

- Centralizes and adds value for the customer, thus increasing satisfaction and loyalty

- Fosters a culture of transparency and mindfulness around efficiency

- Brings disparate teams together to break down silos

- Helps teams and employees see the value their role adds to the company

VSM improves the organization from the inside out; it’s not just the customer that benefits.

Drawbacks of value stream mapping

Before taking on value stream mapping, make sure that your organization is prepared in order to reap the benefits.

Value stream mapping is complex and therefore a time intensive endeavor. Without the right people involved—like a value stream manager or those who have received VSM training—and proper planning, guidance, and execution, VSM can be a waste of time and resources.

Scrutinizing the value stream is also likely to generate fear or distrust from those who are directly involved in creating a product or service. A value stream map might uncover a better way to deploy software updates that requires significant overhaul of current workflows.

VSM may also shed light on understaffed sections of the production process, leading to changes in who works where in the value stream. When management puts processes under a microscope, employees may resist big changes or worry for their position.

Ongoing communication will therefore be crucial to maintain trust and understanding. Value stream mapping, after all, is not about determining which employees to keep or let go. Instead, it’s about analyzing and optimizing workflows. Emphasize and demonstrate a commitment to training and developing employees to help them perform their jobs better.

VSM is worthwhile

Virtually every business today relies on technology. Within enterprises, CIOs should partake in—if not spearhead—value stream mapping projects to see where IT falls short of supporting organizational goals and delivering value to the customer.

Value stream mapping is a visualization process that helps identify and root out sources of waste from code development to review to deployment. VSM also works in an additive manner to help identify and pursue activities or processes that add value to the end product.

For CIOs, VSM helps them find and address inefficiencies in the use, management, or production of technology. VSM also promotes greater collaboration between development and operations to continuously improve the product and keep customers happy.